15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2025 07 04

2025 07 04 Fit H7 is a standard tolerance grade for holes commonly used in CNC machining parts and assemblies. It specifies the permissible size variation with a zero lower deviation and a positive upper deviation depending on the nominal size. Understanding H7 tolerance ensures precise component fits, improving product quality and performance in CNC machining factories.

66

66

Read more

Read more

VMT

VMT  2025 07 03

2025 07 03 18/8 stainless steel is an austenitic alloy composed of approximately 18% chromium and 8% nickel. It offers excellent corrosion resistance, strength, and workability, making it ideal for food-grade, medical, and industrial applications. Often equivalent to 304 stainless steel, it is widely used in CNC machining services to produce hygienic, durable, and visually appealing stainless steel CNC machining parts.

66

66

Read more

Read more

VMT

VMT  2025 07 02

2025 07 02 To choose between 3Cr13 stainless steel and 316 stainless steel, it’s critical to compare corrosion resistance, hardness, machinability, and cost. For cost-effective CNC machining parts, 3Cr13 offers balanced performance; for harsh environments and food-grade demands, 316 stainless steel CNC machining parts deliver superior durability.

66

66

Read more

Read more

VMT

VMT  2025 07 01

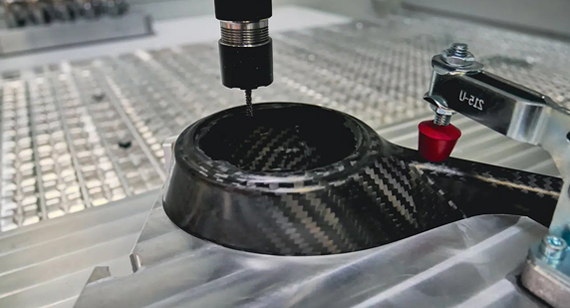

2025 07 01 Composite CNC machining is the process of using computer numerical control to shape and fabricate parts made from composite materials, such as carbon fiber, fiberglass, and aramid-reinforced polymers. It requires specialized tools and techniques to prevent delamination, maintain precision, and achieve high-performance results across industries like aerospace, automotive, and medical.

66

66

Read more

Read more

VMT

VMT  2025 06 30

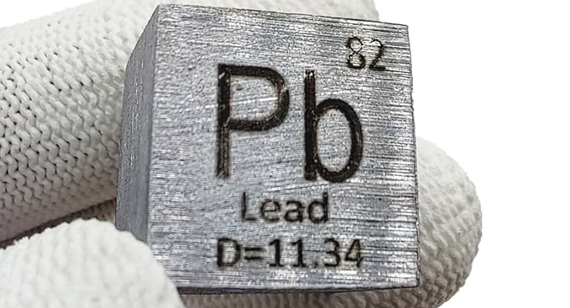

2025 06 30 Lead has a standard density of approximately 11.34 g/cm³, equivalent to 11,340 kg/m³ or 0.410 lb/in³. This makes it one of the densest commonly used metals in CNC machining parts, especially where weight, shielding, and vibration control are required.

66

66

Read more

Read more

VMT

VMT  2025 06 28

2025 06 28 Fiberglass is a composite material made from fine glass fibers and resin, offering excellent strength-to-weight ratio, corrosion resistance, and thermal insulation. It is widely used in aerospace, automotive, marine, construction, and industrial applications, and can be precisely manufactured using fiberglass CNC machining services for high-performance parts.

66

66

Read more

Read more

VMT

VMT  2025 06 27

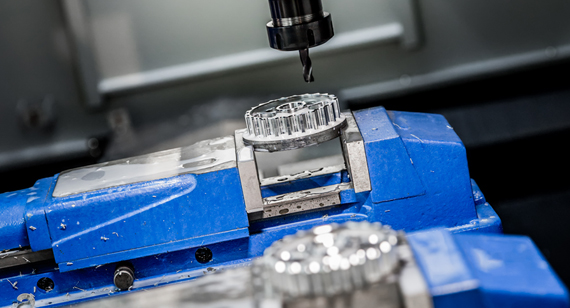

2025 06 27 Choosing the right milling machine can feel overwhelming. With dozens of designs, axis configurations, and control types available, buyers often struggle to match a machine’s capability with their manufacturing needs. The wrong decision can lead t

66

66

Read more

Read more

VMT

VMT  2025 06 26

2025 06 26 DFM planning ensures design-to-manufacture alignment by identifying and resolving manufacturing challenges early. It optimizes part geometry for CNC machining, recommends tooling strategies and surface-treatment processes, prevents costly redesigns, and accelerates prototype sampling. The result: faster lead times, controlled costs, improved quality, and a smoother transition to production.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!