15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 23 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 23 2026 | Reading Time:About 2 minutes

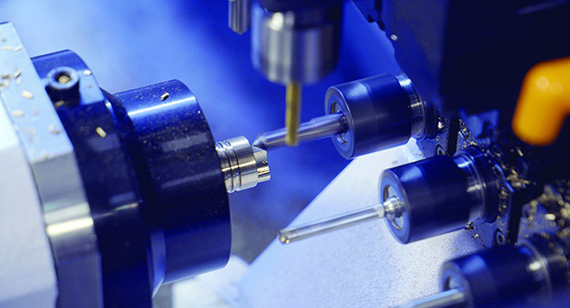

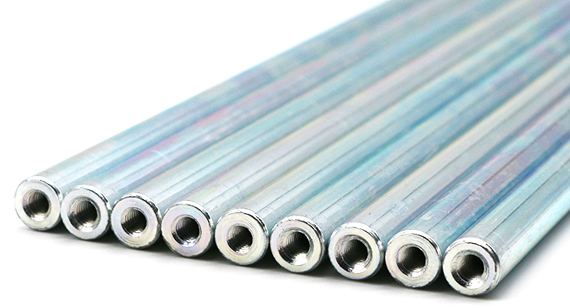

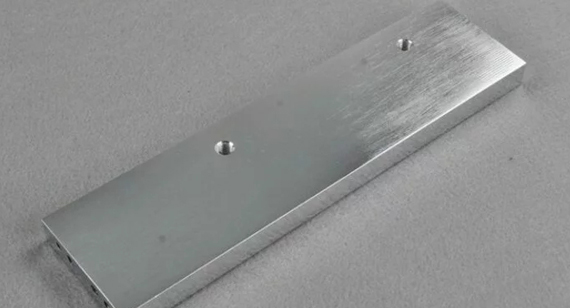

In the field of precision CNC machining, selecting the right material is key to balancing part quality with production costs. If you are producing high volumes of complex parts—such as fasteners, hydraulic/pneumatic components, timing gears, miniature shafts, or precision bushings—11SMn30 (EN 1.0715) steel may be your best CNC machining carbon steel.

As a non-alloy, low-carbon free-cutting steel, 11SMn30 is renowned for its exceptional machinability. This article explores its material properties, the pros and cons of processing, environmental considerations, and how it helps you achieve cost-effectiveness in CNC machining.

11SMn30 is a non-alloy low-carbon free-cutting steel named according to the European standard EN 10087, with material number 1.0715. In older standards, it was often referred to as 9SMn28. Its US equivalent is AISI 1213 / 1215. Commercial names include Green Cut 2715 or M-Steel.

The name "11SMn30" reflects its primary elements: approximately 0.11% Carbon and 0.30% Sulfur. By controlling sulfur and phosphorus content, fine manganese sulfide (MnS) inclusions are formed within the material. These inclusions act as "built-in lubricants" and "chip breakers" during machining, making it one of the most machinable steels globally.

1.1 Chemical Composition of 11SMn30

The following table details the chemical composition and the role of each element in 11SMn30 steel:

Table 1: Chemical Composition and Elemental Roles of 11SMn30

| Component |

Content (%) |

Role |

| Carbon (C) |

≤ 0.14% (typically ~0.11%) | Maintains good toughness and ductility. |

| Manganese (Mn) |

0.90 – 1.30% | Combines with sulfur to form manganese sulfide, enhancing machinability. |

| Sulfur (S) |

0.27 – 0.33% | Promotes chip breaking and reduces tool wear. |

| Phosphorus (P) |

≤ 0.11% | Helps improve machinability and surface hardness. |

| Silicon (Si) |

≤ 0.05% | Kept low to optimize free-cutting performance. |

1.2 Physical and Mechanical Properties

The table below shows the primary physical and mechanical properties of 11SMn30:

Table 2: Physical and Mechanical Properties of 11SMn30

| Property |

Value |

| Material No. |

1.0715 |

| Density |

7.85 g/cm³ |

| Melting Point |

1420 - 1460°C |

| Tensile Strength (Rm) |

360 - 540 MPa (As rolled) |

| Yield Strength (Rp0.2) |

245 - 440 MPa (As rolled) |

| Elongation (A) |

6 - 9 % |

| Brinell Hardness (HB) |

107 - 169 |

| Thermal Conductivity |

40 - 50 W/(m·K) |

| Relative Magnetic Permeability |

~100 (Ferromagnetic) |

| Metallic Luster |

Distinct / Bright (Peeled) |

The standard density of 7.85 g/cm³ and high melting point indicate it possesses the fundamental physical properties of carbon steel. Furthermore, the material exhibits fundamental metallic properties, including high magnetic permeability, excellent thermal conductivity, and a distinct metallic luster. However, due to its high-sulfur free-cutting nature, it sacrifices weldability and structural reliability. It is a "precision machining material" rather than a "structural construction material." Its moderate tensile and yield strengths also reflect its primary use in components bearing low-to-medium loads.

Choosing CNC machining for 11SMn30 steel offers significant advantages in boosting productivity, reducing costs, and ensuring part quality. The following factors explain why 11SMn30 is a preferred material for CNC machining.

Excellent Chip Breaking

In automated CNC lathe machining, a big headache is long, spiral chips tangling around the tool. The sulfur in 11SMn30 makes chips short and brittle, allowing them to be ejected automatically. This enables machines to run unattended for long periods, greatly increasing production efficiency.

High Cutting Speeds and Feed Rates

Compared to standard carbon steels (such as 1018 or 1045), 11SMn30 allows for significantly higher cutting speeds (SFM). Within the same production window, the output of 11SMn30 parts is typically 30% higher than that of ordinary steel. The high production speed means that the production cycle of the product is greatly shortened.

Extended Tool Life

Due to lower cutting forces and reduced frictional heat, wear on CNC tools is significantly minimized. This results in less downtime for tool changes and lower consumable costs—a factor that can save a fortune on high-volume orders.

Superior Surface Finish

Even without additional grinding, 11SMn30 produces a very smooth surface finish that meets the strict aesthetic and dimensional accuracy requirements of most industrial parts. The smooth surface finish is also beneficial for subsequent surface treatments—such as zinc plating, electroless nickel plating, or other coatings—thereby enhancing the corrosion resistance of the parts and extending their service life.

11SMn30 is a low-cost carbon steel containing sulfur and phosphorus, so its raw material cost is already affordable compared to stainless steel and other alloy steels. Beyond that, 11SMn30 carbon steel can further reduce overall CNC machining expenses thanks to its excellent machinability. Its easy-cutting behavior not only reduces tool wear but also improves machining speed—important because machining time typically accounts for 60%–80% of a CNC project’s total cost. Using 11SMn30 can cut costs in several ways:

Therefore, 11SMn30 combines low material cost with reduced machining time, less downtime, and fewer finishing steps—providing multiple levers to lower total CNC machining cost.

Although 11SMn30 free-cutting steel is pick-tip choice for CNC machining, it still has some other limitations you may watch out when considering this steel:

Poor Weldability

Due to high sulfur and phosphorus content, 11SMn30 is highly susceptible to "hot cracking" during welding. Welding is generally not recommended.

Lower Tensile Strength

Compared to alloy steels like 4140 or 4340, its strength is lower, making it unsuitable for high-load structural components.

Unsuitable for Through-Hardening

Because the carbon content is extremely low, it cannot be hardened through conventional quenching (case hardening is usually the only option).

For years, 11SMnPb30 (leaded free-cutting steel) was the industry standard. However, as environmental regulations like RoHS and REACH become stricter, lead-free 11SMn30 is becoming the mainstream choice.

Environmental Advantage

11SMn30 contains no lead, complying with global green manufacturing standards and eliminating export compliance risks.

Performance Comparison

While leaded steel might be 5-10% faster to machine, modern 11SMn30 (like "M-Steel" variants) has virtually closed this gap through optimized metallurgy. For most applications, 11SMn30 is the preferred choice for balancing performance and environmental responsibility.

The low-carbon steel 11SMn30 is unlike a stainless steel, it lacks the necessary chromium content to form a protective passive layer against corrosion. So, it is highly prone to rusting. Therefore, surface treatment is almost always required in practical applications. Below, I will introduce each suitable surface treatment for 11SMn30 from the perspectives of process, use examples, expected results, and cost, and provide recommendations.

Electroless Nickel Plating

11SMn30 (EN 1.0715) represents the ultimate balance between performance and cost-efficiency in the world of carbon steel machining. Its self-lubricating properties and excellent chip breaking make it the indisputable king for high-volume CNC production. By choosing 11SMn30, manufacturers can ensure precision and high surface quality while simultaneously reducing cycle times and tool replacement costs, making it the premier choice for sustainable and profitable manufacturing.

A European hydraulic systems supplier required a monthly output of 20,000 precision hydraulic hose fittings. The part featured a complex internal thread and a micro-reduced neck section, demanding tight dimensional tolerances, excellent surface finish and high fatigue resistance. The customer initially planned to manufacture the part from standard 1020 low‑carbon steel using conventional turning processes, but early trials exposed several issues: short tool life, high cutting temperatures, long cycle times and inconsistent surface quality. These problems threatened the supplier’s ability to meet volume, cost and quality targets.

VMT Evaluation and Proposed Solution

Following a detailed manufacturing feasibility review and material performance analysis, VMT CNC machining factory recommended switching the material from 1020 to 11SMn30 (EN 1.0715). The decision was guided by material machinability and long‑term part performance considerations:

Manufacturing Approach and Key Process Elements

Machines and cooling

Tooling and cutting strategy

Fixtures and automation

Quality assurance and process control

Measured Results and Business Impact

After pilot runs and process validation, the production rollout delivered measurable improvements:

Q1: What is the difference between 11SMn30 and leaded steel (like 11SMnPb30)?

A: 11SMnPb30 (1.0718) includes added lead (Pb) for even higher machining speeds. However, due to global environmental regulations (RoHS/REACH), lead-free 11SMn30 is the preferred eco-friendly alternative for companies focusing on sustainability and trade compliance.

Q2: Can 11SMn30 be heat treated?

A: Since the carbon content is very low (~0.11%), it cannot be conventionally through-hardened. If you need high surface hardness, Case Hardening is the solution, providing a hard exterior while maintaining a tough core.

Q3: How is the rust resistance of 11SMn30?

A: As a carbon steel, it rusts easily in humid environments. We recommend surface treatments like zinc plating, electroless nickel, or black oxide after machining.

Q4: Why is 11SMn30 not recommended for welding?

A: The high sulfur content (0.3%) causes "hot shortness," leading to cracks in the weld. Mechanical fasteners or specialized brazing are recommended for joining.

Q5: Is 11SMn30 magnetic?

A: Yes. Like most low-carbon steels, 11SMn30 is ferromagnetic. This makes it suitable for applications where magnetic properties are required, though it should not be used as a high-performance soft magnetic alloy.

Q6: Can 11SMn30 be used for food-contact applications?

A: Generally, no. Due to its high sulfur and phosphorus content and its susceptibility to corrosion, it does not meet food safety standards. For food-grade applications, stainless steel (like 304 or 316L) is the appropriate choice.