15 years one-stop China custom CNC machining parts factory

17 |

Published by VMT at Dec 18 2025 | Reading Time:About 2 minutes

17 |

Published by VMT at Dec 18 2025 | Reading Time:About 2 minutes

When it comes to high-performance stainless steels, duplex 2205 stainless steel, with its superior strength, good toughness, excellent corrosion resistance, and cost-effectiveness compared to 304/316 stainless steel, has become one of the perfect choices for industries ranging from marine engineering and chemical processing to oil and gas extraction. It provides engineers and manufacturers with a perfect solution for parts that combine performance and reliability. This article will provide you with a comprehensive understanding of the properties, processing performance and cost, advantages and limitations, and applications of duplex 2025 stainless steel. Through this article, you will understand why duplex 2205 is the optimal choice compared to other stainless steel varieties.

Duplex 2205 is a duplex stainless steel that its microstructure is roughly 50% ferrite and 50% austenite. This unique combination gives the material both high strength and excellent toughness. Unlike fully austenitic stainless steels (like 304 or 316), Duplex 2205 is more resistant to stress corrosion cracking, pitting, and chloride-induced corrosion.

Its chemical composition is designed to stabilize this duplex structure, typically including:

This precise alloying allows Duplex 2205 to offer an excellent combination of strength, toughness, and corrosion resistance, making it suitable for highly demanding applications.

Duplex 2205 stainless steel is recognized internationally under below standards, where convenient for your quick check:

Table 1: Duplex 2205 Stainless Steel – Standards & Designations Reference Table

| Category | Designation Standard | Description |

| EN / European Standard | EN 1.4462 | European standard designation for Duplex 2205 |

| F Series | F51 | Corresponding to UNS S31803 / S32205 |

| ASTM Standards | A182, A240, A276, A479, A789, A790, A815 | Covers forgings, plates, bars, seamless and welded pipes, and pressure vessel components for Duplex 2205 |

| ASME Standards | SA182, SA240, SA479, SA789 | Corresponding ASME standards for boiler / pressure vessel applications |

| International / Offshore Standard | NORSOK MDS D45 – Grade F51 | Offshore / marine / oil & gas platform applications |

| Petroleum Corrosion Standard | NACE MR0175 / ISO 15156 | H₂S-containing environments – sulfide stress cracking resistance |

And here noted that designation of duplex 2205 stainless steel is from old verson of UNS S31803 to updated UNS S32205.

Mechanical Properties of Duplex 2205 Stainless Steel

2205 duplex stainless steel holds the property of high strength compared to standard austenitic stainless steels (304,306 stainless steels). Mechanical properties of Duplex 2205 giving it that yield strength is nearly double that of 316 stainless steel , as well as toughness even at low temperatures, and good fatigue resistance under dynamic loading. All of these makes Duplex 2205 ideal for pressure vessels, offshore structures, pumps, valves, and load-bearing components.

Table 2: Mechanical Properties of Duplex 2205 Stainless Steel (Compared to 304,306 Stainless Steel)

| Property | Duplex 2205 | 304 stainless steel | 316 stainless steel | Performance of duplex 2205 |

| Tensile Strength | 620–880 MPa | ~570 MPa | ~620 MPa | Better |

| Yield Strength | ≥ 450 MPa | ~215 MPa | ~290 MPa | Better |

| Hardness | ~30 HRC | ~18 HRC | ~22 HRC | Better |

| Elongation | ~25% | ~40% | ~35% | Better |

Duplex stainless steel 2205 exhibits superior corrosion resistance in high-chloride and highly corrosive environments, making it an ideal choice over traditional austenitic stainless steels (such as 304 and 316) for applications such as offshore pipeline systems, desalination plants, heat exchangers, and chemical plants. Its balanced austenitic-ferrite microstructure significantly enhances resistance to localized corrosion mechanisms. Compared to the higher-grade Super Duplex 2507, 2205 offers less resistance to pitting corrosion and mechanical strength (2507 is only needed when the environment exceeds the corrosion or strength limits of Duplex 2205).

Key Performance of corrosion-resistance of Duplex 2205 include:

Heat Treatment and Phases

Duplex 2205 is typically supplied in a solution-annealed state(a heat treatment process that involves heating a metal alloy to a high temperature to dissolve or homogenize alloying elements, followed by rapid cooling), with a typical annealing temperature range of 1000–1100°C. Rapid cooling is followed after annealing to ensure the material maintains a balanced ferrite and austenite structure, achieving optimal toughness and corrosion resistance.

Improper heat treatment or exposure to high temperatures can lead to the formation of harmful phases in duplex 2205 stainless steel. It is generally recommended that duplex 2205 not be used for extended periods at temperatures above 300°C (572°F), as even brief exposure to high temperatures can cause embrittlement.

If temperature control is inadequate during processing or service, Duplex 2205 may precipitate several harmful intermetallic phases within a specific temperature range, significantly reducing toughness and corrosion resistance.

When considering the machinability of Duplex 2205 Stainless Steel, you need to pay attention to its challenges when machining and welding. And since machining of duplex 2205 is metioned, you may also need to consider its cost-performance balance compared to the commonly used stainless steel grades (304, 316, 2205, 2507).

CNC Machining Considerations

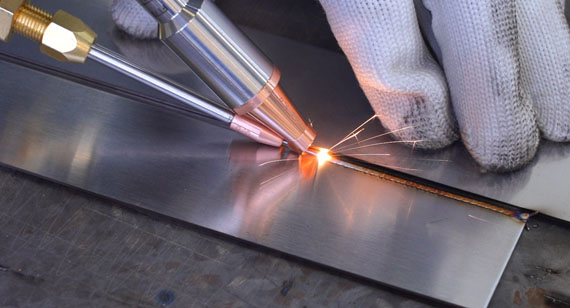

Despite its superior strength and corrosion resistance (compared to 304 or 316 stainless steel), duplex 2205 is more difficult to machine than 304 or 316 stainless steel due to its high strength, easy work hardening, poor thermal conductivity, and abrasive structure. CNC machining is the usual way to machining duplex 2205, it is using cutting tools (where tool movement is controlled by computer programs) to remove material from a solid metal block or plate, forming thin-wall structures . The typical workflow includes CAD → CAM Programming → Workpiece Setup → Machining (turning, milling, drilling)

Due to its difficulty to machine, there are son CNC machining recommendations:

Through these strategies, Duplex 2205 can be precision machined into durable and corrosion-resistant parts.

Welding and Fabrication Considerations

Proper welding processes can maintain the strength and corrosion resistance of duplex steel 2205, ensuring long-term performance in harsh applications such as marine and chemical processing.

Because 2205 steel inevitably experiences a sensitive temperature range of 600–1000°C during welding (where harmful phases are prone to form), Duplex 2205 is particularly susceptible to the formation of harmful phases such as the σ phase during welding, especially under conditions of excessive heat input, slow cooling, or nitrogen loss due to inappropriate shielding gas.

To maintain a balanced duplex structure of 2205 in the weld and heat-affected zone:

When evaluating material options for strength, corrosion resistance, and economic efficiency, the cost-performance balance among Duplex 2205, stainless steels 304 and 316, and Super Duplex 2507 is worth noting.

Table 3: Comparing the Duplex 2205, stainless steels 304 and 316, and Super Duplex 2507

| Material | Relative Cost | Strength | Corrosion Resistance | Machining/Welding Difficulty |

| Duplex 2205 | Upper-Mid | High (~2× 304) | High (especially chloride resistance) | Moderate |

| 304 | Low | Medium | Medium-Low (not suitable for severe chloride environments) | Easy than others |

| 316 | Medium | Medium | Medium-High (Mo improves chloride resistance over 304) | Easy than 2205,2507 |

| Super Duplex 2507 | High | High | Extremely High (best chloride resistance) | High difficulty in machining and strict welding requirements |

Understanding the advantages and disadvantages can help you understand the adaptability limitations of 2205 duplex stainless steel, and determine whether it is a suitable choice for your parts machining.

Advantages of Duplex 2205 for Machined Parts

High strength, good toughness, excellent fatigue resistance and corrosion resistance of Duplex 2205 make it ideal for demanding industries such as:

This article presented duplex 2205 stainless steel, explained what it is, and discussed its properties, machining and applications. To learn more about duplex 2205 stainless steel (or other types of stainless steel 304,316,ect if needed), contact a VMT representative.

VMT CNC machining factory provides a wide range of manufacturing capabilities and other value-added services(high precision machining, surface finishes,etc.) for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Is Duplex 2205 stainless steel magnetic?

Yes, it exhibits magnetism due to its ferritic content, unlike fully austenitic grades.

How resistant is Duplex 2205 to UV exposure?

It has excellent UV resistance.

Can Duplex 2205 be hardened or anodized?

It can be hardened, but it is not suitable for anodizing.

What are the electrical properties of Duplex 2205 stainless steel?

The electrical resistivity of Duplex 2205 (78.4–81.6 μΩ·cm) , which means it is a poor conductor, mainly suitable for structural rather than electrical applications.

How does alloy 2205 duplex stainless steel sheet differ from the plate?

Sheets are thinner and ideal for cladding, fabrication, or corrosion-resistant panels, while plates are thicker for structural applications.

What is the duplex 2205 stainless steel alloy price per kg?

A rough guide is $8–14/kg , but your final price will vary depending on exact grade, form, finish, and quantity.