15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2026 01 17

2026 01 17 High-lead tin bronze, renowned for its application in self-lubricating bearings, is a highly machinable material with excellent wear resistance and good thermal conductivity. Although it generally falls within the medium-strength range, this does not hinder its exceptional performance in harsh, polluted industrial environments. From marine to automotive components, the self-lubricating properties provided by lead make this alloy particularly effective in preventing the interference of dirt and debris on the surface, ensuring reliable operation. Additionally, the tin content determines the hardness and toughness of high-lead tin bronze while heterogeneous of the alloy is also affected by the material's Tin content. Read on for a more detailed and comprehensive understanding of high-lead tin bronze.

66

66

Read more

Read more

VMT

VMT  2026 01 16

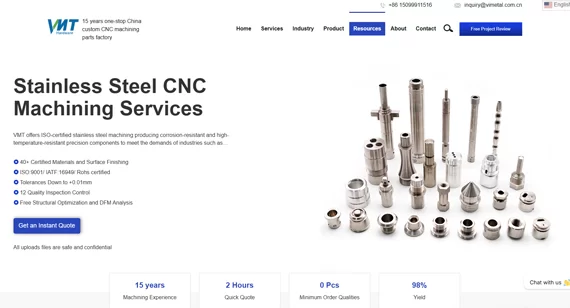

2026 01 16 In modern manufacturing, high-precision stainless steel CNC machining is critical to ensuring product performance and project success. From complex aerospace structural components to precision medical device parts, selecting the right manufacturer directly impacts quality and efficiency. Leading Stainless Steel CNC Machining Manufacturers not only offer strict tolerance control and multi-material processing capabilities, but also provide unique machining advantages and local rapid-response services. This article highlights 30 top manufacturers worldwide, covering China, the USA, and other countries, helping you quickly identify reliable partners for efficient and dependable production.

66

66

Read more

Read more

VMT

VMT  2026 01 15

2026 01 15 Have you ever wondered which aluminum alloy is the strongest? 7075 aluminum alloy is the alloy with the highest strength compared to other aluminum alloys. You might find this material is widely used in aerospace, high-load automotive structures, and high-end bicycle components. But even for blast-resistant shields and components of specialized sniper rifles, 7075 aluminum can be in the material lists. Besides its high strength, it also has key characteristics of average corrosion resistance, high hardness, good fatigue resistance, a high strength-to-weight ratio, and poor weldability. Read on to learn more about 7075 aluminum’s properties, uses, forms, and pros and cons.

66

66

Read more

Read more

VMT

VMT  2026 01 14

2026 01 14 This article will take you through its chemical composition, mechanical and physical properties, processing recommendations, main applications, and a comparison with common aluminum alloys, giving you a comprehensive look at 8011 aluminum and helping you quickly grasp its core performance and practical uses.

66

66

Read more

Read more

VMT

VMT  2026 01 13

2026 01 13 You may have heard 6063 alloy that’s often called the extruded aluminum alloy, which is especially popular in building aluminum profile industry. But, about this member of the 6xxx series alloy, it’s not only for the alloy’s characteristics of outstanding extrudability, corrosion resistance, and weldability, but also for it’s differences of properties under T5 / T52 / T6 temper effect its value in engineering and manufacturing. For a more detailed discussion about aluminum 6063 alloys, you will find more in the sections below.

66

66

Read more

Read more

VMT

VMT  2026 01 12

2026 01 12 CNC machining technology plays an indispensable role in the production of modern high-precision engine components. It transforms raw materials into high-quality engine parts with stable dimensional accuracy and complex geometries. Especially for custom applications, CNC offers advantages in speed, efficiency, precision, and cost. This guide will provide you with a comprehensive overview of the main CNC machining processes, engine part types, typical materials, as well as key benefits and challenges, giving you a complete overview.

66

66

Read more

Read more

VMT

VMT  2026 01 11

2026 01 11 5086 aluminum finds extensive applications in ship hulls, armor plates, offshore structures, pressure vessels, and storage tanks. Recognized for its exceptional durability and corrosion resistance, it performs reliably even in harsh environments such as seawater and salt spray. The alloy also offers excellent weldability and can achieve enhanced strength through cold working, making it a versatile choice for a wide range of engineering applications. Read on to explore more details that make 5086 aluminum a trusted material.

66

66

Read more

Read more

VMT

VMT  2026 01 10

2026 01 10 4943 aluminum provides engineers and fabricators with a reliable welding solution that combines durability, corrosion resistance, and excellent weldability. Developed as a higher-strength alternative to ER4043, this aluminum–silicon filler metal delivers improved as-welded mechanical performance while maintaining excellent crack resistance and arc stability. Beyond its role as a filler metal, 4943 aluminum contributes significantly to the structural performance of welded assemblies, making it widely used in automotive frames, aerospace components, HVAC systems, marine structures, and other load-bearing aluminum fabrications where joint strength and dimensional stability are critical. This guide covers the composition, properties, typical applications of 4943 aluminum, and compares it with other commonly used AWS ER filler alloys, including ER4043, ER4047, and ER5356.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!