15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 25 2026 | Reading Time:About 3 minutes

0 |

Published by VMT at Jan 25 2026 | Reading Time:About 3 minutes

When it comes to versatility in manufacturing, AISI 1018 steel (also known as Grade 1018 Mild Steel) is the undisputed workhorse of the industry. Known for its excellent balance of strength, ductility, and affordability, this low-carbon steel is a staple in CNC machining, prototyping, and sheet metal fabrication.

In this guide, we will dive deep into what makes 1018 steel unique, properties and composition, material selection about 1018 steel with other alloys, its machining and surface protection, heat treatment and hardening by carburizing.

AISI 1018 (commonly called 1018 steel, Grade 1018, or AISI/SAE 1018) is a versatile low-carbon mild steel with an average carbon content around 0.18%. It’s widely used across machining, fabrication, and general-purpose engineering because it balances cost, manufacturability, and mechanical performance. This steel is popular due to it has characteristics of:

Depending on where you are sourcing your materials, 1018 steel may go by different names:

Table 1: Equivalents of 1018 Steel in Different Regions

|

Country |

Designation |

| United States (ASTM/SAE) |

AISI 1018 / ASTM A108 |

| China (GB) |

20# / 20 / ML18 |

| Japan (JIS) |

S15C / S20C |

| European Union (EN) |

C15 / C18 / S235 |

| Germany (DIN) |

Ck15 / 1.1141 / 1.0401 |

| United Kingdom (BS) |

080M15 / En3B |

| France (AFNOR) |

XC18 / XC15 |

| International (ISO) |

C18 |

| Russia (GOST) |

18ps / St20 |

The "18" in 1018 represents its carbon content—approximately 0.18%. Other simple composition include 98.81% - 99.26% lron (Fe) as the base metal;0.60% - 0.90% Manganese (Mn) added to increase the material's strength; Phosphorus(P) ≤ 0.04% and Sulfur (S)≤ 0.05% as the trace elements.

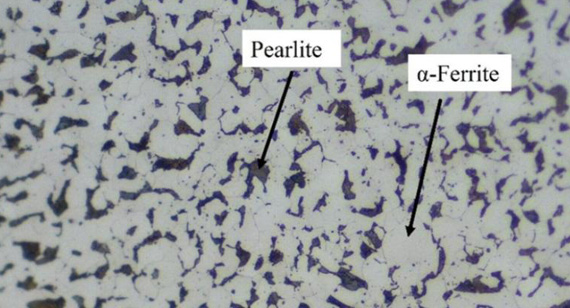

At a microscopic level, 1018 steel is a mix of Ferrite (the softer, highly ductile part) and Pearlite (the harder, stronger part). This combination allows the metal to be easily formed while maintaining enough strength for structural use.

You can find mechanical, physical and thermal properties in below table 2:

Table 2: Key Properties of AISI 1018 Steel

| Category |

Property |

Typical Value |

Design & Practical Significance |

| Mechanical |

Machinability Rating | 70% – 78% (relative to AISI 1212) | High efficiency; reduces tool wear and allows for superior surface finishes during CNC operations. |

| Weldability | Excellent | Low carbon content minimizes cracking risk; weldable via MIG, TIG, and resistance methods without pre-heating. | |

| Ductility (Elongation) | 15% – 20% | Capable of significant deformation (bending, swaging, flaring) before structural failure. | |

| Yield Strength | 370 MPa (53,700 psi) | The point at which the material begins to deform permanently; reliable for load-bearing machinery parts. | |

| Physical |

Density | 7.87 g/cm³ (0.284 lb/in³) | Standard for low-carbon steel; used for mass/center-of-gravity and weight calculations in part design. |

| Magnetic Behavior | Ferromagnetic | Retains strong magnetic response; suitable for electromagnetic assemblies and sensors. | |

| Melting Point | ~1410°C – 1510°C (2570°F – 2750°F) | High-temperature stability; melting range depends on exact composition/impurities. | |

| Thermal |

Thermal Conductivity | 51.9 W/(m·K) (at 100°C) | Effective heat dissipation during high-speed machining and thermal cycling in service. |

| Coeff. of Thermal Expansion | 11.5–13.9 µm/m-°C | Moderate expansion; must be accounted for in tight-tolerance assemblies or dissimilar metal mating. |

One of the biggest limitations of 1018 steel is that it cannot be deep-hardened (also the through-hardened, a heat treatment that makes a steel part uniformly hard, strong, and wear-resistant throughout its entire cross-section) because there isn't enough carbon to transform the entire core into martensite.

However, it is the best steel for carburizing (case hardening). By diffusing carbon into the surface layer at high temperatures, you can create a part with a glass-hard exterior and a tough, ductile core. And carburizing is a critical part of the overall heat treatment process.

Common Heat Treatment Processes of 1018 Steel

Comparison: Surface Hardness Before & After Heat Treatment

You can find surface hardness of 1018 mild steel in its different stages in below table:

Surface Hardness of 1018 Mild Steel in Different Stages

| State of 1018 Steel |

Surface Hardness (Rockwell) |

Tensile Strength (PSI) |

Characteristics |

| Standard (As Rolled) |

~70-80 HRB | 58,000 | Soft, ductile, easy to bend |

| Cold Drawn (CRS) |

~80-90 HRB | 64,000 | Better finish, slightly harder |

| After Carburizing/Case Hardened |

55 - 62 HRC | N/A (Surface only) | Good wear-resistant surface |

| After Annealing |

~50-60 HRB | 50,000 | Maximum softness for forming |

What are Functions of Carburized AISI 1018 Steel

AISI 1018 is widely used for many machined and heat‑treated parts because of its favorable balance of machinability, formability, and response to surface hardening. The Carburized AISI 1018 Steel's processing logic can be separated into two practical stages:

Before carburizing — excellent machinability and formability

After carburizing — “hard exterior, tough core”

Typical parts that exploit the “hard case / tough core” of carburized 1018 include:

What is CNC Machining and Prototyping with 1018 Steel?

CNC Machining 1018 Steel is the process of using CNC machinery—such as mills and lathes—to automatically cut and shape 1018 low-carbon steel into finished parts. 1018 Steel Prototyping refers to the rapid production of initial functional models or test samples using this specific material and technology.

Why 1018 Steel is Ideal for CNC Machining and Prototyping?

The popularity of 1018 steel is primarily due to its exceptional machinability, tool-friendliness, and excellent surface finish.

1018 steel is widely used in the manufacturing of various non-critical structural components and mechanical parts:

Does 1018 steel rust? Yes, easily. Like most carbon steels, it lacks the chromium content found in stainless steel.

To prevent oxidation of 1018 steel, various surface treatments are recommended:

Black Oxide: Provides a sleek black look and mild rust resistance.

It is a chemical conversion coating. The steel is submerged in a hot, alkaline salt solution (caustic soda and nitrates) which triggers a chemical reaction that converts the surface iron into magnetite, a black iron oxide. It adds negligible thickness (1–2 microns), making it ideal for high-precision CNC parts where tight tolerances must be maintained. It provides a sleek, non-reflective matte finish and mild corrosion resistance when oiled.

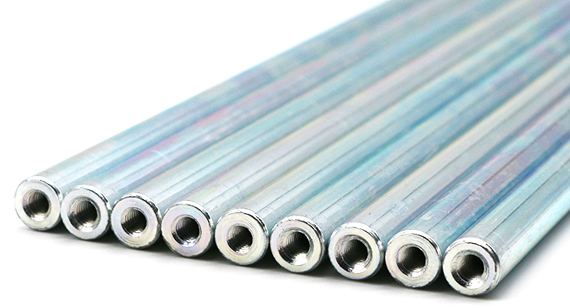

Zinc Plating: A sacrificial layer that prevents corrosion.

It is an electroplating process. The 1018 steel part is placed in an electrolyte bath, and an electric current is used to deposit a thin layer of metallic zinc onto the surface. It offers sacrificial protection. Zinc is more chemically active than iron; therefore, the zinc layer will corrode (sacrifice itself) first to protect the underlying steel, even if the coating is scratched. This is the standard for nuts, bolts, and automotive fasteners.

Powder Coating: Best for structural parts exposed to the elements.

It is an electrostatic spray deposition. A dry powder (typically a polymer resin) is electrostatically charged and sprayed onto the grounded 1018 steel part. It provides a thick, durable barrier that is much tougher than liquid paint. It is highly resistant to impact, UV rays, and harsh weather, making it the best choice for structural brackets and outdoor machinery.

Chrome Plating: For high-wear applications and aesthetic shine.

It's a complex electroplating process where a layer of chromium is deposited over the steel. You can choose this surface treatment for high-wear applications or aesthetic shine. Hard chrome is perfect for high-wear moving parts like hydraulic rods or pistons while decorative chrome provides a mirror-like shine that does not tarnish, making it ideal for high-end aesthetic applications.

When choosing a steel grade, the right question is not “Which is best?” but “Which is best for my purpose?” Below are concise, purpose-driven comparisons that highlight where AISI 1018 shines and where higher-carbon or alloy steels are preferable.

Precision machining and prototyping — choose 1018 steel

High strength and load-bearing components — choose 1045 and 4140

General structural members — A36

A36 (structural carbon steel) is optimized for welded, bolted, and riveted building/structural applications. It is economical, readily available in plates and sections, and designed to meet structural yield and ductility requirements.

AISI 1018 steel is the perfect choice for projects where ease of fabrication and cost-efficiency are priorities. Whether you are building complex CNC-machined components or simple structural brackets, understanding its response to heat treatment and surface finishing will help you maximize the performance of this mild carbon steel material.

A manufacturer of hydraulic systems needed to produce a batch of 1018 steel hydraulic manifolds. Despite 1018 being classified as a "free-machining" steel, the customer encountered two critical bottlenecks in their previous cooperated CNC machining plant:

VMT CNC Machining Factory resolved these issues through the following methods:

1. Digitized Cutting Parameter Modeling:

2. Real-Time In-Process Monitoring:

Automated Probing: CNC centers were equipped with automated tool-wear sensors. The system captured dimensional data every 20 cycles, automatically applying offsets to the CNC controller to compensate for the slight abrasive wear caused by the manganese content in 1018 steel.

The implementation of VMT’s optimized process yielded the following good results:

Q: Is material 1018 steel expensive?

A: No. It is one of the most economical steels available due to its simple composition and wide market availability.

Q: Why is stainless steel more corrosion-resistant than 1018 carbon steel ?

A: Stainless steel contains at least 10.5% Chromium, which forms an invisible, self-healing protective layer. 1018 has negligible chromium.

Q: What are the main advantages of material 1018 steel?

A: Exceptional weldability, high ductility, excellent machining properties, and perfect response to case hardening.

Q: What are the main disadvantages of material 1018 steel ?

A: Low corrosion resistance and the inability to be through-hardened for high-strength core requirements.

Q: What is the difference between Hot Rolled (HR) and Cold Finished (CF) 1018 steel?

A: Cold Finished 1018 has a smoother surface, tighter dimensional tolerances, and higher strength due to work hardening, whereas Hot Rolled is more cost-effective but has a rougher scale finish and less precise dimensions.

Q: Can 1018 steel be used for high-wear parts like heavy-duty gears?

A: Only if it is case-hardened (carburized). In its raw state, it is too soft for high-wear applications, but case hardening creates a very hard outer shell while maintaining a ductile, shock-resistant core.